Machine design

Machine week was an exciting and tyring one, being in the CBA group was quite a thrill. Everything went on pretty fast since the first meeting, it felt quite confusing but also really fun.

The first meeting was all about brain storming ideas, we all coincided that we wanted to make something cool but also useful or doable as we had only 7 days to do it. It was quite a pleasure to work with the CBA as the whole team was quite determined and willing to use all of the potential of the shops and machines that we have available.

First ideas were constrained by the 4 axis restriction since the beggining so we went from an geoprinting extruder to a piano playing machine to finally agree on a lathe. This discussion was really nice as we coud go around and try to understand how the machines in the shop worked, they al worked as examples and I learned a lot with this process. Brainstorming session was fun as we all had a say on what we eanted to do. This session was also important as I could visualize my final project better.

After agreeing on making an apple peeler we divided into different groups, ACT offered to make a documentation video and help with the hardware group, at the end we ended up looking at every part of the process as we had to document everything. This part was really interesting as I got to ask a lot of questions and try to understand how this machines work and how they are designed.

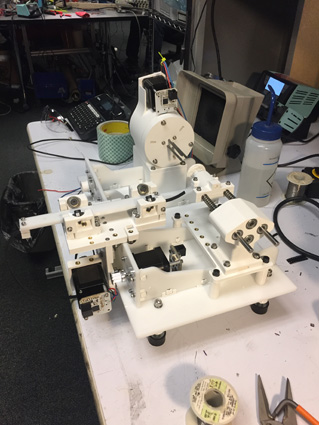

First day alfonso did a prototype based on the machine Jake designed, we offered to 3d print some parts of this machine and got familiar with Fusion, seeing it work was amazing and I look forward to learn more about it, we got the entire design on fusion and took the different parts that needed to be printed, downloaded the to the 3d printer software we have available at ACT and ran about 120 pieces that came out quite well.

The second try for bigger pieces was quite a mess and it was quite frustrating as they took about 14 hours to print and failed almost halfway through, the computer kept on breaking also so we spent the entire day trying to fix this problem. The pieces came out fine eventually but it was a very frustrating time.

As time went by we had several general meeting that were very usefull, I believe the workflow was very convenient as these meeting felt as a way to regroup and have different strategies on where we were standing in the process. They were also very useful to break down the tasks that needed to be done between all of us. Git came out really handy as we used it as a communication platform, we also decided to document everything in a tracking webpage so that everyone was aware of what was happening, Git is a great tool and I'm looking forward to learn more about the possibilities of group working with it.

As different tasks were distributed we documented most of the process, we created a Dropbox folder for everyone to upload their videos and photos and in this way documentation was more efficient as we couldn't see all of what was happening all the time. Me and Po Hao helped assemble the first prototype for the machine and solved some minor issues with the motor piece which was having some friction with one of the fasteners.

Editing the video took longer than expected as we had to condense a los of work in a few minutes, it started as a 2 minute video but due to the amount of pictures and videos that we took all together we ended uo with a 5 minute video, making this video meant understanding the process and being able to comunicate it in a short amount of time. It was a great way to contribute but also to learn about the workflow of such a crazy endeavour. Late nights all weekend and non stop work during the seven days payed off when the first prototype showed sign of life.

As the week progressed, the work started to pile up and a lot of things where happening. We decided to take some qeuipment from the ACT checkout in order to document sound and different media that was coming out.

This part was really fun because this where sounds that where present in the whole process, being inmersed in such a fast and intense way of working brings people together and makes communication weirder, we tried to document this part also and the video shows part of these ways of non verbal comunication.

As wednesday came closer we had to take a long night to finish the editing of the video, I believe we were able to capture most of the feeling of the process and the rapid flow of ideas. I also got to see and work with the different groups and got to learn a lot about machine design, constraints, machining, manufacturing, software and interfaces.

Amazing time with amazing people!